At this year’s ISPO, Polartec is proud to announce Power Fill – the latest in fabric innovation. An ingenious discovery that’s resulted in an incredibly warm, one-of-a-kind, fill insulation.

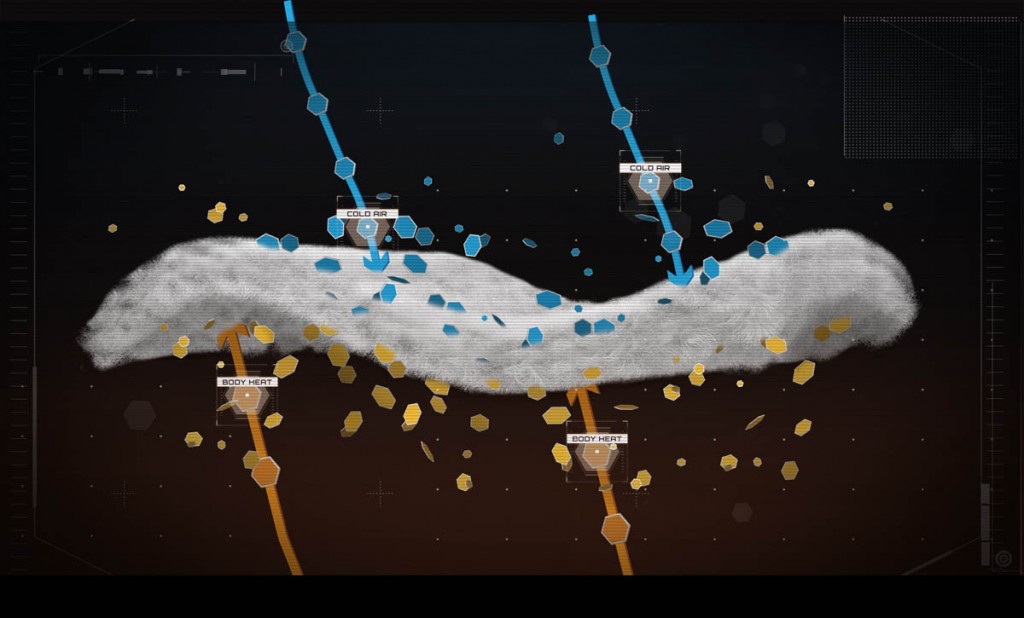

Using a matrix of hollow polyester fibres, engineered into a distinct geometric pattern, Power Fill forms thousands of air pockets allowing warm body heat to be continuously captured and contained inside.

Sponsored feature

However it’s Polartec’s melting process which bonds these fibres, thereby increasing their durability and drapability, that gives giving Power Fill its unmatched warmth and design versatility. The unique design pulls Power Fill apart from the competition as it eliminates the need for scrims or other stabilisers – resulting in a fill that’s easier to sew and transport and doesn’t inhibit breathability. The perfect combination for clothing manufacturers.

Made with industry-leading, cruelty-free, 80 per cent post-consumer recycled content, Power Fill insulation technology provides greater warmth retention in colder conditions, without added weight or bulk. Power Fill is available in four different weights – 60, 80, 100 and 135 g/m2.

“We’re proud to deliver an insulation technology to our customers that enables the design of better products with Polartec premium quality,” says Polartec CEO Gary Smith. “Polartec created the category of active insulation with our industry leading range of Alpha temperature regulating product offerings, and now Power Fill continues with innovative fill solutions for the coldest conditions.”

Visit Polartec at Booth B4 328 at this year’s ISPO to see Power Fill in the flesh in Millet’s new generation midlayer Elevation Airloft Hoodie for autumn-winter 2018.

Aimed at demanding alpinists, Millet specifically chose Power Fill for this performance jacket. The new weave means the jacket is particularly light and more compressible than standard fill. Millet concentrates the warmth of Power Fill in the most important areas, allowing mobility and breathability at the same time.

Millet’s new thermal mid layer also offers a balaclava hood that can be worn under a helmet, a single large chest pocket for an ultra-minimalist design and a double-slider front zip for use with a harness. Just the job for serious mountaineers and climbers looking for their next winter challenge.

Power Fill is the premium choice for manufacturers looking for low-weight warmth with hydrophobic properties. It’s clear to see Polartec has produced the ultimate insulation that also resists moisture absorption and dries quickly.

The warmth without weight mantra is one that Polartec adheres to in many of the fabrics it creates, but what the company really sees as the new frontier is the need for more and more versatility in fabrics. Polartec aims to make fabrics that are usable, in other words comfortable, in as wide a range of conditions as possible. Succeeding at that means that their customers can design garments with much more freedom than ever before and the end user can utilise the garment in many more ways than ever.

People are most conscious about the garments they are wearing when they are not working well, when they are making them uncomfortable. Polartec aims to make materials that can make the wearer forget about the clothes and get on with their activity.

The Elevation Airloft Hoodie, which uses the new Polartec insulation, will be available in autumn-winter 2018

Of course, it’s not the first time Polartec has kept us warm. The fabric technology company has a heritage stretching back more than a century. It began as the family-owned Malden Mills of Massachusetts in 1906 – producing wool-knit bathing suits, workmen’s sweaters and uniforms to keep American soldiers warm through two World Wars.

But it was in 1981 that Polartec would revolutionise our outdoor wardrobes forever with PolarFleece – a synthetic wool alternative that could wick away moisture from the skin whilst keeping the wearer toasty warm. Even Time Magazine described ‘fleece’ as one of the 20th century’s greatest inventions, setting the premium standard for lightweight warmth and comfort.

Since then, Polartec has continued in its mission to keep us warm, dry and comfortable.

ISPO will give manufacturers the chance to feel and sample many of the other innovative fabrics created by Polartec. Including Alpha – another great choice for cold conditions. Alpha is a base fabric originally developed for the US Special Forces after they asked for a more advanced insulating material in their combat uniforms.

Now with updated technology, Alpha’s active insulation and adaptable breathability regulate core body temperature both during dynamic and static activities. This means the wearer doesn’t have to add or remove layers whilst exercising, whether stopping or starting. A revolution in comfort and ease.

And Polartec Delta, for when the sun finally comes out! A cooling, next-to-the-skin fabric that uses one of the body’s most natural processes – sweating. Delta fabric works harder and smarter than even the adventurer wearing it, due to its specialised elevate knit construction, which lifts the fabric’s yarns. This results in increased airflow, more moisture dispersal and reduced friction against the skin.

Furthermore, where cotton tends to swell with water and wet out, creating a barrier to breathability, and polyester dries so quickly it can result in a painful flash cool in the wind, Polartec Delta uses natural fibres for immediate long term cooling and synthetics for a faster drying time. Keeping the wearer not too hot and not too cool.

Furthermore, where cotton tends to swell with water and wet out, creating a barrier to breathability, and polyester dries so quickly it can result in a painful flash cool in the wind, Polartec Delta uses natural fibres for immediate long term cooling and synthetics for a faster drying time. Keeping the wearer not too hot and not too cool.

Polartec will be showcasing many of its new and exciting, soon-to-be-on offer products with those manufacturers who trust Polartec for their fabric designs at this year’s ISPO. Including mountain sport brand, Salewa, professional glove maker, Reusch and famed outdoor brand, Berghaus. Pay them a visit to learn about the science of fabric.